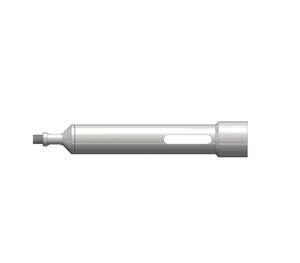

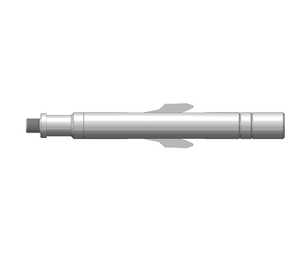

Cast Iron Bridge Plug

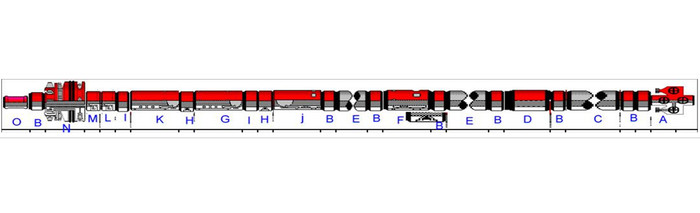

Product Parameters

Product Parameters

BPmatebridgeplu

What Does Cast Iron Bridge Plug (CIBP) Mean?

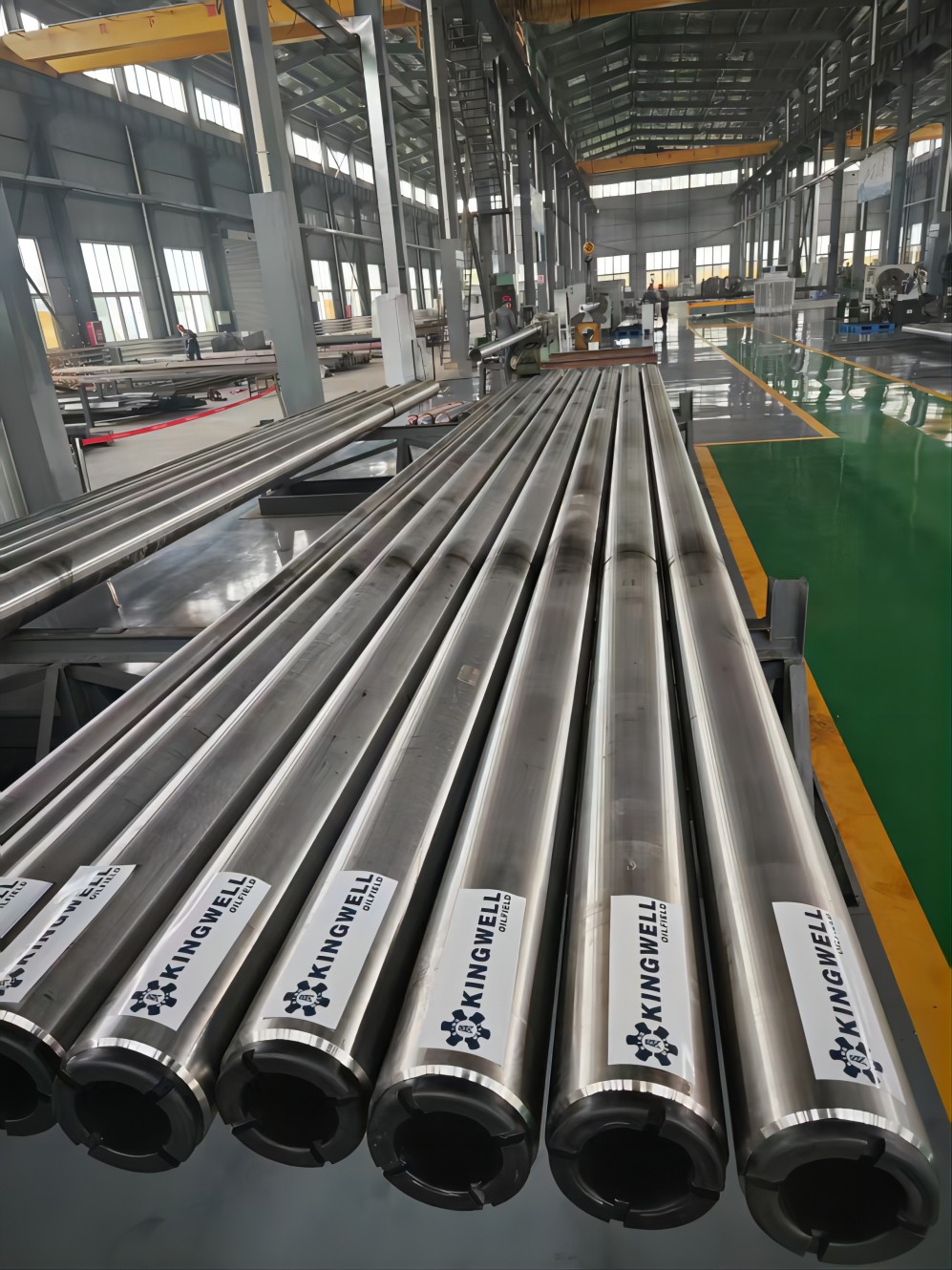

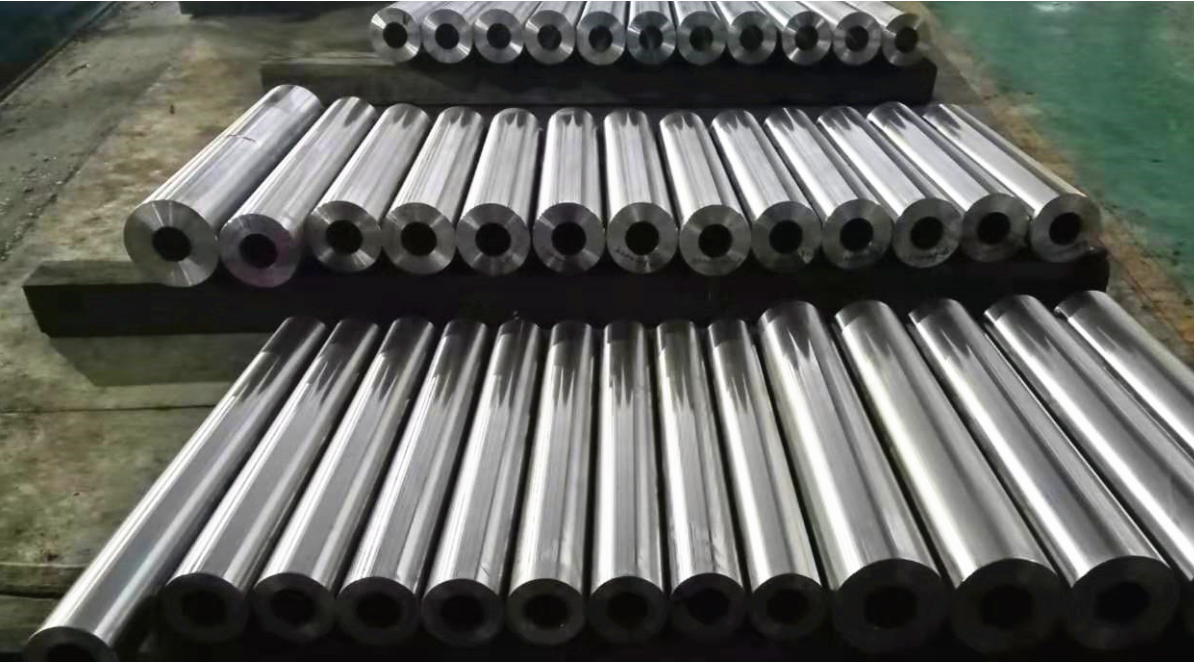

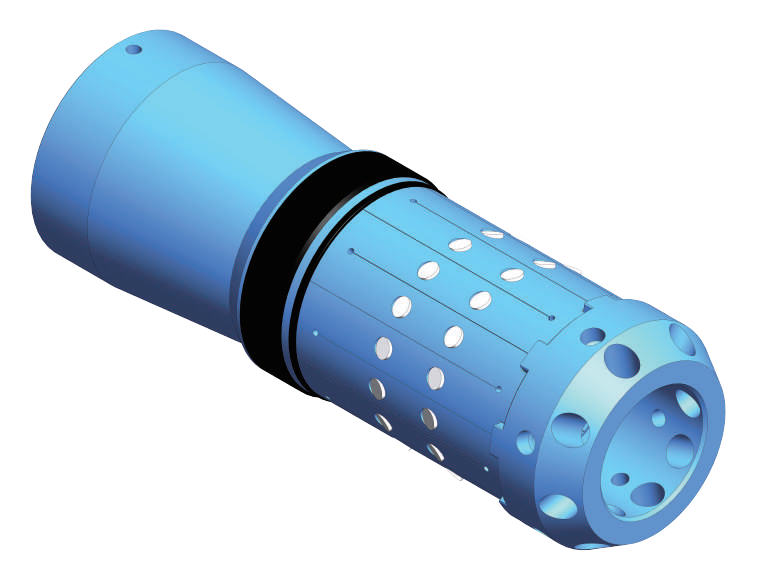

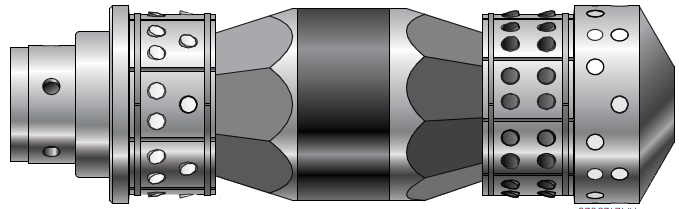

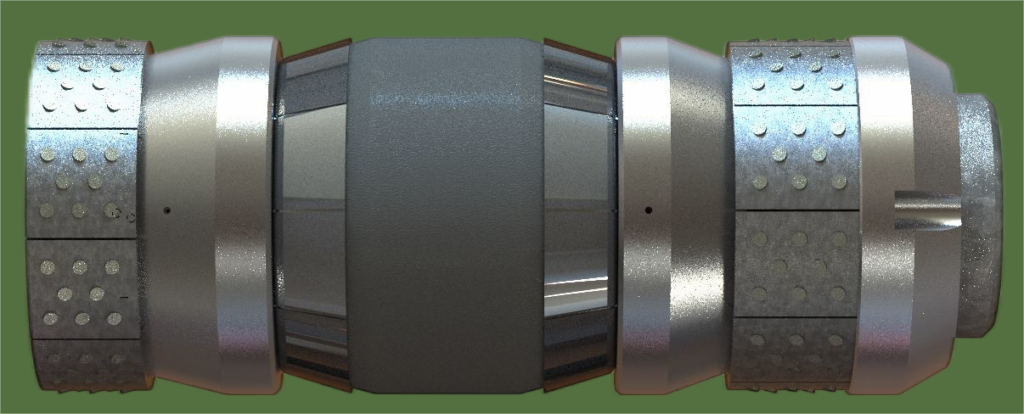

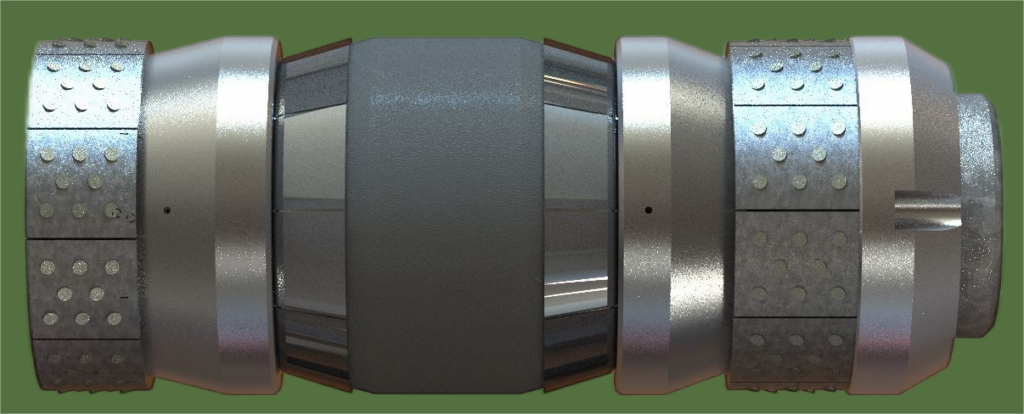

MBP's cast iron bridge plug (CIBP) is a high-pressure plug made of drillable cast iron that can be used to isolate a section of the well. It can be easily set using a pipe or coil tubing or a wireline pressure setting tool. It is highly dependable and widely used in the oil and gas industry.

MBP's CIBP is used for well-abandonment, zonal isolation, stimulation, and casing pressure tests. It is available for tubing and casing sizes from 4" to 20" and is easy to drill out due to the cast iron material.

How To Explain Cast Iron Bridge Plug (CIBP)?

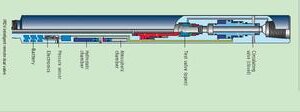

MBP's cast-iron bridge plug (CIBP) is considered as one of the most dependable and effective isolation plugs available. It can be permanently set in tubing or casing and is capable of withstanding large pressure differentials and high temperatures.

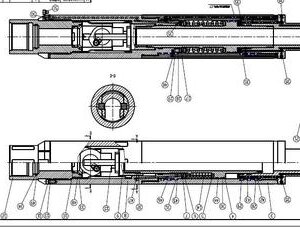

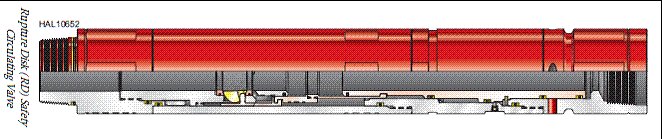

It can be designed with shorter lengths to provide a shorter drill out time to save time and cost. It uses setting sleeves and adapter rods and can be set on wireline tool or pipe tubing. The opposing slips are located above and below the rubber packing elements which are contained by back-up rings that eliminate element extrusion at high temperature and pressure. An adequate amount of cement or sand has to be placed over the plug to prevent damage to the plug from perforating shock.

How To Remove a CIBP?

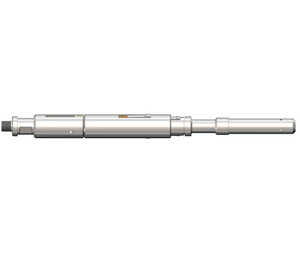

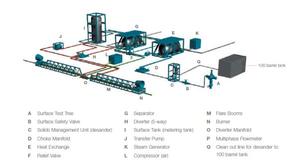

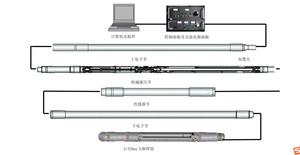

To bring back the wellbore to the production stage, the CIBP has to be removed. This can be done under pressure, in the absence of kill-weight fluids. The removal technology consists of a collection of thru-tubing fishing equipment (mills and motors), remedial or simulation equipment (composite bridge plug), and coiled tubing.

The thru-tubing fishing equipment allows the CIBP to be drilled without pipe rotation. The coiled-tubing conveys mills and motors as a bottomhole assembly downhole to provide maximum efficiency for the drill-out operation.

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559