Tool Accessories

Product Parameters

Product Parameters

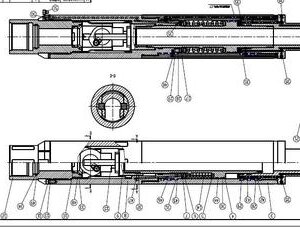

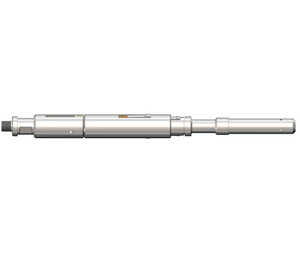

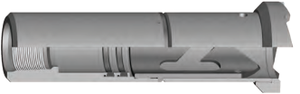

DT-2 ON/OFF TOOL

The DT-2 On/Off Tool is a tubing seal receptacle allowing isolation of a lower zone using a wireline blanking plug. Thetubing string can then be removed from the well. When re-run,the tubing string automatically re-engages to the stinger,and the blanking plug can be retrieved by wireline. The DT-2 On/Off Tool is run above an ASI-X Packer, a VSI-X Packer or a Permapak Seal Bore Packer with a latch seal mandrel.

NOTE:Stingers sold separately.

Special Features

Blanking plug seats in top of stinger to prevent debris build-up

Bonded seal allows disconnects and re-connects

Right-hand or left-hand release

Milling shoe allows rotation through debris

Product Specifications

Casing / Tubing Size (inches) | Tool OD(inches) | Thread Connections Box Up |

2-7/8 | 2.250 | 1.900 NUE |

1.900 EUE | ||

3-1/2 | 2.750 | 1.900 EUE |

4 | 3.250 | 1.900 EUE |

3.125 | 2-3/8 EUE | |

4-1/2 | 3.437 | 1.900 EUE |

3.580 | 1.900 EUE | |

3.656 | 2-3/8 EUE | |

3.750 | 2-3/8 EUE | |

5 | 3.750 | 2-3/8 EUE |

4.250 | 2-3/8 EUE | |

5-1/2 | 4.375 | 2-3/8 EUE |

4.500 | 2-3/8 EUE | |

4.406 | 2-7/8 EUE | |

4.500 | 2-7/8 EUE | |

6-5/8 | 5.500 | 2-3/8 EUE |

2-7/8 EUE | ||

3-1/2 EUE | ||

7 | 5.875 | 2-3/8 EUE |

2-7/8 EUE | ||

5.250 |

| |

5.875 | 3-1/2 EUE | |

7-5/8 | 6.375 | 2-7/8 EUE |

3-1/2 EUE | ||

4-1/2 EUE | ||

8-5/8 | 7.500 | 2-7/8 EUE |

3-1/2 EUE | ||

4-1/2 EUE | ||

9-5/8 | 8.250 | 2-7/8 EUE |

3-1/2 EUE | ||

4-1/2 EUE | ||

10-3/4 | 9.310 | 3-1/2 EUE |

4-1/2 EUE | ||

11-3/4 | 10.000 | 2-7/8 EUE |

13-3/8 | 11.875 | 4-1/2 EUE |

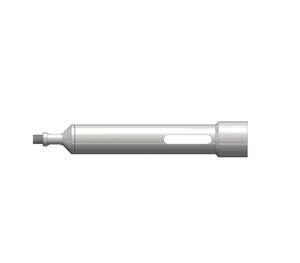

PROFILE NIPPLE

![]()

The Profile Nipple is designed to allow common slickline plugs and equipment to be placed successfully downhole. API and Premium threads can be cut on the nipples to reduce crossovers. Common profile and sizes are available.

Special Features

ID profiles made per customer requirements

API and Premium threads available

“F”, “R”, “DX”, and “DXN” profiles available

CRA trim available

Product Specifications

Tubing Size (inches) | Profile Size (inches) | Profiles |

1.900 | 1.500 | DXDXN |

2-3/8 | 1.437 | F |

1.500 | FRDX DXN | |

1.625 | F | |

1.781 | FR | |

1.812 | FR | |

1.875 | FRDXDXN | |

2-7/8 | 1.812 | F R |

1.875 | FRDXDXN | |

2.130 | R | |

2.187 | FR | |

2.250 | FR | |

2.312 | RDXDXN | |

3-1/2 | 2.250 | F |

2.312 | DX | |

2.562 | FR | |

2.750 | FRDXDXN | |

2.812 |

|

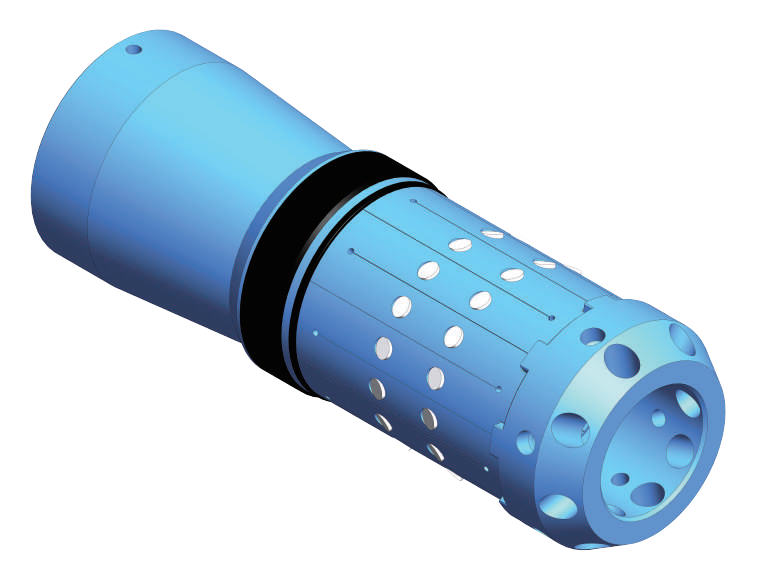

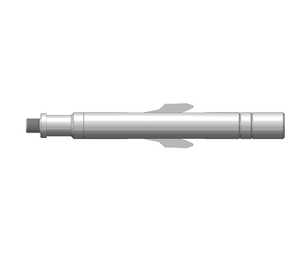

BIT RELEASE JOINT

The Bit Release Joint is used in operations for drilling out cement, cast iron bridge plugs, composite bridge plugs, and other drillable tools and thereby leaving the drill string intact as the production string. The spring loaded check valve prevents tubing back-flow during drill out. After drill out, a ball is dropped through the drill string and seats in the piston. Pressure applied to the drill string forces the drill bit to release and fall to the bottom of the hole.

Special Features

Simple design

Dual float option

Full opening after release

High shear option available

Product Specifications

Thread Connections | Tool OD (inches) | |

Top | Bottom | |

2-3/8 EUE | 2-3/8 REGULAR TOOL JOINT | 3.500 |

2-7/8 EUE | 2-7/8 REGULAR TOOL JOINT | 3.750 |

4” IF TOOL JOINT | 4-1/2 REGULAR TOOL JOINT | 6.500 |

SAFETY JOINT -SHEAR, ROTATIONAL & SWIVEL SHEAR

The Safety Joint allows positive release of the tubing string in completions where retrieval problems are anticipated. These safety joints are available in straight pull shear release, rotational release, and swivel shear release versions.

Product Specifications - Shear Safety Joint

| |

Tubing Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

1-1/4 | 2.060 | 1.25 | 1-1/4 NPT |

1.660 | 2.063 | 1.25 | 1.660 NUE |

1.900 | 2.300 | 1.50 | 1.900 NUE |

2.500 | 1.50 | 1.900 EUE | |

2-3/8 | 3.063 | 2.00 | 2-3/8 EUE |

2-7/8 | 3.688 | 2.50 | 2-7/8 EUE |

3-1/2 | 4.500 | 3.00 | 3-1/2 EUE |

4 | 5.000 | 3.50 | 4” EUE |

4-1/2 | 5.560 | 4.00 | 4-1/2 EUE |

5 | 5.560 | 4.50 | 5” LTC |

5-1/2 | 6.050 | 4.67 | 5-1/2 LTC |

Product Specifications - Rotational Safety Joint

Tubing Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

1.660 | 2.250 | 1.38 | 1.660 NUE |

1.900 | 2.500 | 1.61 | 1.900 EUE |

2-3/8 | 3.060 | 2.00 | 2-3/8 EUE |

2-7/8 | 3.690 | 2.50 | 2-7/8 EUE |

3-1/2 | 4.250 | 3.00 | 3-1/2 NUE |

4.500 | 3.00 | 3-1/2 EUE | |

4-1/2 | 5.200 | 4.00 | 4-1/2 EUE |

5.000 | 4.00 | 4-1/2 LTC |

Product Specifications - Swivel Shear Safety Joint

Tubing Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

2-3/8 | 3.060 | 2.00 | 2-3/8 EUE |

2-7/8 | 3.690 | 2.50 | 2-7/8 EUE |

3-1/2 | 4.500 | 3.00 | 3-1/2 EUE |

4-1/2 | 5.560 | 4.00 | 4-1/2 EUE |

4-1/2 LTC | |||

5.000 | 3.92 | 4-1/2 LTC |

PUMP-OUT PLUG

The Pump-Out Plug is available with a variety of threads allowing installation to the bottom of the tubing string to isolate the tubing from the annulus. To remove the plug, pressure is applied to the tubing and the Pump-Out Plug is removed to allow full opening. The pump-out pressure value is easily adjusted in the field by adding or removing shear screws.Also available with ball seat.

Special Features

Ball seat available

Adjustable shear value (high shear available)

Special Pump-Out Plug designs available

Product Specifications

Tubing Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connection Box Up |

1.050 | 1.660 | - | 1.050 EUE |

1.315 | 1.900 | 1.20 | 1.315 EUE |

1.660 | 2.062 | 1.38 | 1.660 NUE |

2.200 | 1.38 | 1.660 EUE | |

1.900 | 2.500 | 1.50 | 1.900 EUE |

2.200 | 1.50 | 1.900 NUE | |

2-3/8 | 3.060 | 2.00 | 2-3/8 EUE |

2-7/8 | 3.670 | 2.50 | 2-7/8 EUE |

3-1/2 | 4.500 | 3.46 | 3-1/2 EUE |

2.88 | 3-1/2 EUE | ||

4-1/2 | 5.560 | 4.00 | 4-1/2 EUE |

4-1/2 LTC | |||

5-1/2 | 6.000 | 5.13 | 5-1/2 LTC |

6-5/8 | 7.390 | 6.23 | 6-5/8 LTC |

7 | 7.650 | 6.60 | 7” LTC |

8-5/8 | 9.620 | 8.18 | 8-5/8 LTC |

9-5/8 | 10.620 | 9.17 | 9-5/8 LTC |

DOWNHOLE TUBING/CASING SWIVEL

The Downhole Tubing/Casing Swivel isolates tools, casing, or tubing from rotation above. Bronze bearing rings insure smooth rotation under load. Simple design allows for easy tool redress.

Special Features

Simple design for easy redress

Full casing/tubing ID

Product Specifications - Tubing Swivel

Tubing Size (inches) | Swivel OD (inches) | Swivel ID (inches) | Thread Connection Box Up / Pin Down |

1.900 | 2.750 | 1.43 | 1.900 EUE / 1.900 NUE |

2-3/8 | 3.580 | 2.00 | 2-3/8 EUE |

3.750 | 2.00 | 2-3/8 EUE | |

2-7/8 | 4.400 | 2.50 | 2-7/8 EUE |

3-1/2 | 5.000 | 3.00 | 3-1/2 EUE |

4 | 4.500 | 3.38 | 4” NUE |

4-1/2 | 5.750 | 4.00 | 4-1/2 LTC |

6.000 | 4.00 | 4-1/2 EUE | |

5 | 5.875 | 4.50 | 5” LTC |

6.250 | 4.50 | 5” LTC | |

5-1/2 | 6.450 | 4.80 | 5-1/2 LTC |

Product Specifications - Casing Swivel

Casing OD (inches) | Swivel OD (inches) | Swivel ID (inches) | Thread Connection Box Up / Pin Down |

7 | 8.500 | 6.25 | 7” LTC |

6.50 | 7” BUTTRESS | ||

9-5/8 | 12.000 | 9.00 | 9-5/8 LTC |

9-5/8 BUTTRESS | |||

9-5/8 LTC |

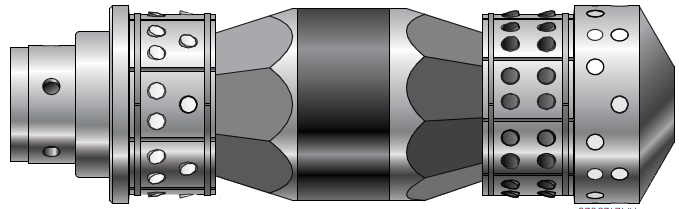

CROSS FLOW ASSEMBLY

The Cross Flow Assembly is designed to allow for a fluid path between the casing annulus and tailpipe below a packer. It primarily is used for gaslift operations where gas from above a set retrievable production packer is directed through the packer and tailpipe to be used to lift produced fluids. The produced fluids and gas are routed through the Cross Flow Assembly into the production string. The ported sub on bottom allows long tailpipe sections below the packer since the weight of the tailpipe hangs on the bottom of the packer.

The Cross Flow Assembly is designed to screw into the top of a standard retrievable production packer (such as an ASI- X Packer). The setting and retrieving of the production packer is not altered by the addition of the Cross Flow Assembly.

Special Features

Simple design

Easily re-dressed

Adaptable to different retrievable packers

Product Specifications

Tubing Size (inches) | Production ID (inches) | Vent ID (inches) | Thread Connection Box Up / Pin Down |

1.900 | 1.19 | 0.62 | 1.900 NUE w/1/4” NPT PORT |

2-3/8 | 1.12 | 0.62 | 2-3/8 EUE |

2-7/8 | 1.63 | 0.88 | 2-7/8 EUE / 2-3/8 EUE |

3-1/2 | 2.00 | 2.00 | 3-1/2 EUE |

4 | 3.50 | 2.00 | 2-3/8 NUE / 4” NUE |

2.00 | 2.00 | 4” NUE | |

5 | 2.50 | 2.39 | 2-3/8 EUE |

5-1/2 | 1.25 | 0.88 | 2-7/8 EUE |

5-3/4 | 2.00 | 2.00 | 4” NUE |

7 | 1.25 | 1.25 | 3-1/2 EUE |

2.50 | 2.50 | 5” LTC | |

2-3/8 EUE | |||

1.25 | 1.25 | 3-1/2 EUE |

EXPANSION JOINT

The Expansion Joint is used to allow expansion and contraction during injection or production operations. They are also used between packers to allow stroke for setting and releasing packers and provides for rotation through the tool. Available with optional seals for low to high temperatures and in lengths up to twenty (20) feet.

Special Features

Pinned (P/N 537xx)

Splined (Keyed) (P/N 538xx)

Clutched (P/N 539xx)

Thermal (P/N 532xx)

Combinations of two or more options available in one tool.

Product Specifications

Tubing Size (inches) |

1.900 |

2-3/8 |

2-7/8 |

|

4 |

4-1/2 |

5 |

5-1/2 |

7 |

9-5/8 |

PUMP-OUT CEMENTING SLEEVE

The Pump-Out Cementing Sleeve is used for cementing tubing strings in both cased and open holes. It allows for internal parts to be pumped out after the cementing process leaving a full open bore with no loss of tubing strength. It is available in a variety of materials. A basket or packer placed below the sleeve provides a seal-point for pumping cement up the outside of the tubing string.

Special Features

Full ID after pump out

Simple design

Adjustable shear value

Product Specifications

Size (inches) | Tool OD (inches) | Ball Seat ID (inches) | ID After Pump Out (inches) | Thread Connections Box Up / Pin Down |

2-3/8 | 3.250 | 1.00 | 1.93 | 2-3/8 EUE |

2-7/8 | 3.750 | 1.25 | 2.40 | 2-7/8 EUE |

3-1/2 | 4.410 | 1.25 | 2.90 | 3-1/2 EUE |

4 | 4.630 | 1.25 | 3.45 | 4” NUE |

4-1/2 | 5.500 | 1.25 | 3.97 | 4-1/2 LTC / 4-1/2 STC |

5-1/2 | 6.130 | 1.25 | 4.63 | 5-1/2 LTC |

TYPE E VALVE

The Type E Valve converts double-grip mechanical packers like the ASI-X Packer into Retrievable Bridge Plugs. The valve is in the open position when running and closed by left-hand rotation after setting the packer. When retrieving, the valve is opened by the rotation required to release the packer. Safety dogs lock the tool and valve together during running and retrieving.

Special Features

Valve locked closed

Bonded seals

Equalized before releasing packer

Safety interlock when running and retrieving

Product Specifications

Size (inches) | Tool OD (inches) | Thread Connection Pin Down |

1.900 | 2.130 | 1.900 NUE |

2-3/8 | 3.094 | 2-3/8 EUE |

2-7/8 | 3.094 | 2-7/8 EUE |

3-1/2 | 4.344 | 3-1/2 EUE |

4-1/2 | 4.750 |

|

RUNNING TOOL - FOR TYPE E VALVE

The Running Tool for the Type E Valve is designed to be used with the Type E Valve to convert double grip mechanical packers (like the ASI-X Packer) into a retrievable bridge plug. This Running Tool features cutting teeth on the running shoe for breaking up compacted trash for easy removal. Running shoes are available in different OD sizes to aid for centering the running tool in larger casing if needed.

Product Specifications

Casing Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connection Box Up |

3-1/2 | 2.750 | 1.16 | 1.900 NUE |

4-1/2 | 3.680 | 1.78 | 2-3/8 EUE |

3.750 | 1.78 | 2-3/8 EUE | |

5-1/2 | 4.500 | 1.78 | 2-7/8 EUE |

2-3/8 EUE | |||

7 | 5.880 | 1.78 | 2-7/8 EUE |

10-3/4 | 9.700 | 3.00 | 4-1/2 EUE |

ANNULUS OPERATED TUBING DRAIN

The Annulus Operated Tubing Drain is an annulus pressure operated drain valve that can be opened to allow fluid to drain from the tubing on a trip out. Shear screws hold the valve closed until enough pressure is applied to the annulus to shear the screws. Once the valve is opened, it cannot be closed.

Product Specifications

Tubing Size (inches) | Tool OD (inches) | Tool ID (inches) | Thread Connections Box Up / Pin Down |

2-7/8 | 3.750 | 2.50 | 2-7/8 EUE |

3-1/2 | 4.750 | 3.00 | 3-1/2 EUE |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559