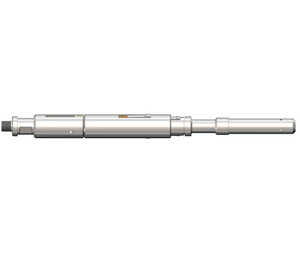

drilling tools _Drill Pipe(drill rod)_KW-DT-031

Product Parameters

Product Parameters

KINGWELL Drill Pipe Features & Benefits:

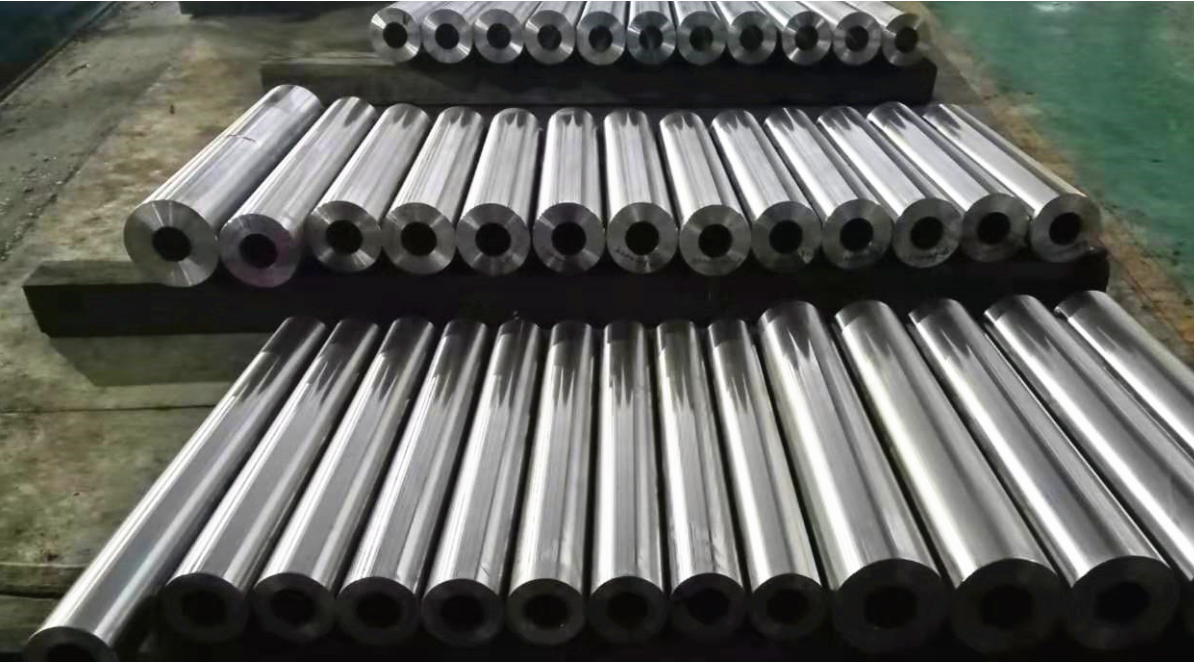

KINGWELL provides oil and gas customers with high quality drill pipe for a wide variety of well profiles, and distributes virtually all sizes of drill pipe for all your drilling needs. Our drill pipes are available with outside diameters (ODs) ranging from 2 3/8" - 6 5/8" . We offer E-75 to S-135 grades, in accordance with API Specification 5D and API Specification 7 as well as proprietary grades for more stringent requirements.

Size: 2 3/8" - 6 5/8" in various lengths.

Steel Grade: E-75, X-95, G-105, S-135 V150

Hardbanding: ARNCO 100XT, 200XT, 300XT, BOTN3000 TCS-Titanium TCS8000 Smoothx

Internal Coating: TK34, TC2000, TC3000 TK70,TK236 TK34XT TK-34P TK70XT

Specification and product level: API SPEC 5DP, API SPEC 7-2, API RP 7G; Tool joint(connection): from NC26 to NC50, 5 1/2FH, 6 5/8FH.

In addition to API/PSL1 and PSL2 drill pipe, KINGWELL offers high standard drill pipe for severe condition drilling service including: API/PSL3, NS-1,DS-1, customers` specifications.

Main Features of Hardbanding:

BoTn is famous for a complete series of high performance anti-wear & friction-reduction hardbanding wires, BoTn1000, Botn3000 and Botn5000. The tests results prove that the materials have perfect performance of anti-wear and friction-reduction under downhole conditions.

BoTn1000: Sufficient hardness (HRC58-62) and good anti-wear property which can triple drill tool joint life. It can be spplied to surfacing welding for new & used tool joint, heavy weight drill pipe and various downhole instruments surface.

BoTn3000: sufficient hardness (HRC58-62) and good anti-wear property which can protect drill pipe to the maximum extent. Perfect friction-reduction properly that can reduce the torque of the drilling string.

BoTn5000: excellent friction-reduction property, which can reduce the casing wear. Tight combination between Botn5000 hardbanding and base metal of tool joint, no spalling, no chipping.

Main Features of Internal Coating:

TC-2000 is epoxy-phenolic material, which can be used in a wide range of temperatures and PH conditions.

TC-2000SS is epoxy-phenolic coating, for use in high temperature and pressure environment of natural gas wells with high content of H 2S and CO 2.

TC2000P is an epoxy-novolac powder coating, which can be used in gas production environments containing H 2S and CO2 with higher temperature(400 ℉)and higher pressure conditions.

NS-1™ Quality and Inspection Requirements for New and Refurbished Drilling and Well Completion Equipment

Liquid Coatings:

TK® 34, TK® 34XT, DPC, TK® 2, TK® 7, TK 21 Tubular, TK® 33, TK® 69.

Powder Coatings:

TK® 15, TK® 70, TK® 70XT, TK® 34P, TK® 216, TK® 236, TK® 505, TK® 800, TK® 805.

An NS-1™ compliance audit and technical review was performed to cover the following processes:-

Management Systems Review – Contract Order Processing – Procurement – Workshop Process – Quality

Control – Inspection + Testing Equipment Calibration and Control – Packaging & Dispatch – Personnel

Competence Assurance Scheme

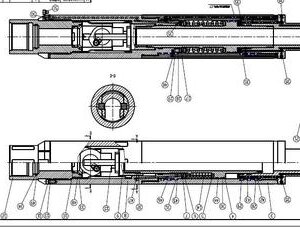

KINGWELL Drill Pipe Technical Data:

| Size | Nominal | OD | Wall Thickness | Grade | Upset Style | Tool Joint | ||

| Weight | ||||||||

| in | lb/ft | in | mm | in | mm | |||

| 2-3/8 | 6.65 | 2.375 | 60.32 | 0.28 | 7.11 | E,X,G | EU | NC26 (2-3/8 IF) |

| 2-7/8 | 10.4 | 2.875 | 73.02 | 0.362 | 9.19 | E,X,G,S | EU | NC31 (2-7/8 IF) |

| 3-1/2 | 13.3 | 3.5 | 88.9 | 0.368 | 9.35 | E,X,G,S | EU | NC38 (3-1/2 IF) |

| 3-1/2 | 15.5 | 3.5 | 88.9 | 0.449 | 11.4 | E,X,G | EU | NC38 (3-1/2 IF) |

| 3-1/2 | 15.5 | 3.5 | 88.9 | 0.449 | 11.4 | S | EU | NC40 (4 FH) |

| 4 | 14 | 4 | 101.6 | 0.33 | 8.38 | E,X,G,S | EU | NC46 (4 IF) |

| 4 | 15.7 | 4 | 101.6 | 0.38 | 9.65 | E,X,G,S | IEU | NC40 NC46 |

| 4-1/2 | 16.6 | 4.5 | 114.3 | 0.337 | 8.56 | E,X,G,S | IEU | NC46 (4 IF) |

| 4-1/2 | 20 | 4.5 | 114.3 | 0.43 | 10.92 | E,X,G,S | IEU | NC46 (4 IF) |

| 5 | 19.5 | 5 | 127 | 0.362 | 9.19 | E,X,G,S | IEU | NC50 (4-1/2 IF) |

| 5 | 19.5 | 5 | 127 | 0.362 | 9.19 | E,X,G,S | IEU | 5-1/2 FH |

| 5 | 25.6 | 5 | 127 | 0.5 | 12.7 | E,X,G | IEU | NC50 (4-1/2 IF) |

| 5 | 25.6 | 5 | 127 | 0.5 | 12.7 | E,X,G,S | IEU | 5-1/2 FH |

| 5-1/2 | 21.9 | 5.5 | 139.7 | 0.36 | 9.17 | E,X,G,S | IEU | 5-1/2 FH |

| 5-1/2 | 24.7 | 5.5 | 139.7 | 0.42 | 10.54 | E,X,G,S | IEU | 5-1/2 FH |

| 6-5/8 | 25.2 | 6.625 | 168.28 | 0.33 | 8.38 | E,X,G,S | IEU | 6-5/8 FH |

| 6-5/8 | 27.7 | 6.625 | 168.28 | 0.362 | 9.19 | E,X,G,S | IEU | 6-5/8 FH |

Other Types of Drill Pipe We Can Do:

KINGWELL Sour Service Drill Pipe

KINGWELL Sour Service Drill Pipe is a type of propriety product with capability of resist to hydrogen sulfide stress corrosion to facilitate the drilling activities in H2S environment.

Size range: Kingwell sour service drill pipe is available for drill pipe ranging in size from 2 3/8 to 6 5/8 inches.

KINGWELL Aluminum Alloy Drill Pipe

KINGWELL Aluminum Alloy Drill Pipe features low specific weight, high flexibility, good corrosion resistance, thus more suitable for extra deep well, horizontal well, high corrosive medium well, directional well and other wells with complicated conditions.

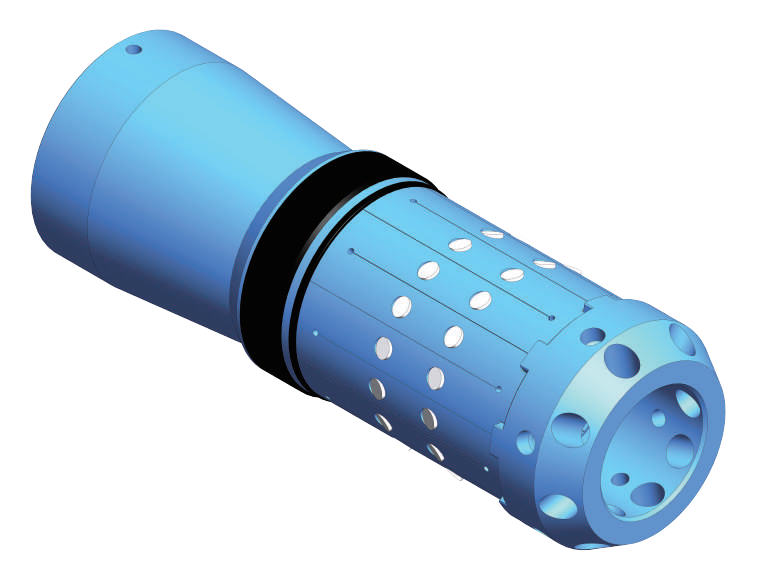

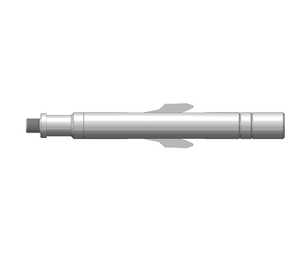

KINGWELL Efficient Cuttings Bed Clean Drill Tool

KINGWELL Efficient Cuttings Bed Clean Drill Tool is proprietary product which designed specifically to improve hole-cleaning performance in horizontal or complex non-conventional wells.

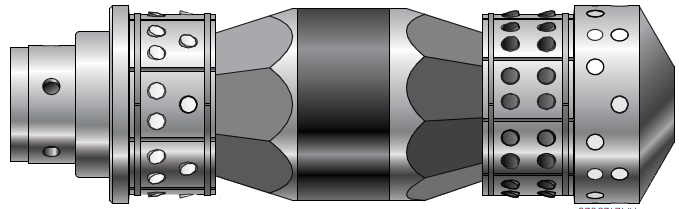

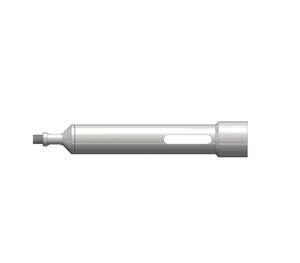

KINGWELL Double-walled Drill Pipe

KINGWELL Double-walled Drill Pipe is composed of two layers drill pipe. It is mainly used in reverse circulation drilling technique. The outside drill pipe is the transmission medium of torque and pressure, the space between outside drill pipe and inside drill pipe is a channel for pumping for circulating medium to well bottom, the inside drill pipe return the circulating medium and rock chips to the outside.

Size Range (OD of external layer pipe): normally 5”, 5 1/2”, 5 7/8”, 6 5/8”, 7 5/8”,8 1/2”, 9 1/2” and 10”.

KINGWELL Non-slip-cut(NSC) Drill Pipe

KINGWELL Non-slip-cut(NSC) Drill Pipe is specially designed for solving problems like the damage to the drill pipe body by the slip cut, the low operation efficiency of double-elevator, and the high labor intensity in the operation of TIH and TOH. This product adds one more shoulder positioned close to the box end than normal API standard drill pipe.

Size range: 4”, 4 1/2”, 5”, 5 1/2”, 5 7/8”, and 6 5/8”

KINGWELL Offshore Casing Landing Pipe

KINGWELL Offshore Casing Landing Pipe is typically used to land heavy casing string in a deep water environment. Designed with sufficient tensile, hoisting and slip-crushing capacity to support the heavy casing string beneath it.

Size range: 5”, 5 1/2”, 5 7/8”, 6 5/8” and 7 5/8”

KINGWELL Arctic Service Drill Pipe

KINGWELL Arctic Service Drill Pipe is a type of propriety drill pipe with capability to perform in extreme cold regions.

Size range: including all API size from 2 3/8 to 6 5/8 inches.

KINGWELL Super High-Strength Drill Pipe

KINGWELL Super High-Strength drill pipes are designed specifically for deep and ultra-deep wells, extended reach drilling (ERD) wells, deep offshore and other critical drilling applications.

Size range: Kingwell high strength drill pipe is available for drill pipe ranging in size from 2 3/8 to 6 5/8 inches.

KINGWELL Slip-protected Drill Pipe

In order to reduce tripping time in the drilling process to improve drilling efficiency, “one elevator one slip” is the general tripping mode. Higher slip crushing capability of the pipe body is required in deep well, extra-deep well and complicated geological conditions. To solve these problems, Kingwell designed and manufactured slip-proof drill pipe, the long thick-walled upset section is designed on the box end.

Size range: 5”, 5 1/2”, 5 7/8”, 6 5/8” and 7 5/8”

KINGWELL Flush-hole Drill Pipe

Kingwell proprietary flush-hole drill pipe is designed to be made-up with the drill pipe body using a special external upset with a large ID. The ID of the tool joint is almost the same as that of the drill pipe body; Decrease annular pressure loss by 20%-50% and improve hydraulic efficiency and drilling speed.

Size range: normally 4 1/2”, 5”, 5 1/2”, 5 7/8”, 6 5/8” and 7 5/8”

KINGWELL HDD Drill Pipe

KINGWELL designed and manufactured the HDD (horizontal and directional drilling) drill pipe meet the large size need, at the same time the rigidity and the thrust also have improved. Special thread design and a guide section adding in the pin thread to prevent the possibility of galling and improve the fatigue capacity, meet the requirement of pipe line horizontal directional drilling engineering.

Size range: normally 5 7/8”, 6 5/8”

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559