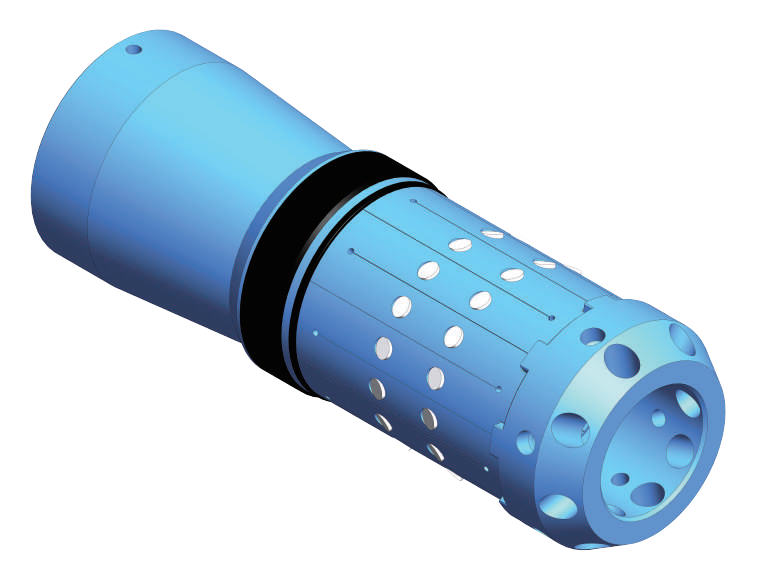

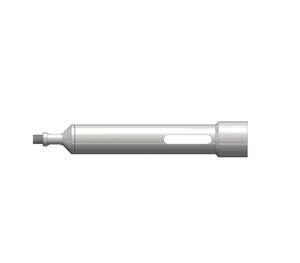

Drilling Jar_SMITH Double-Acting Hydraulic Drilling Jar

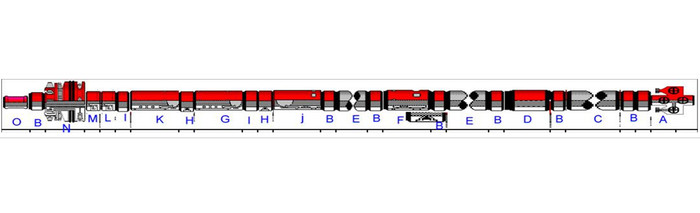

Product Parameters

Product Parameters

High-impact force reliably delivered

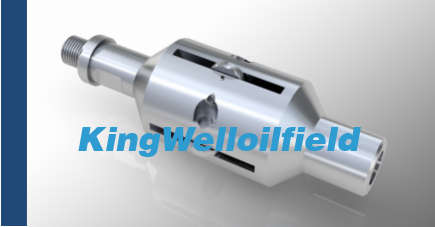

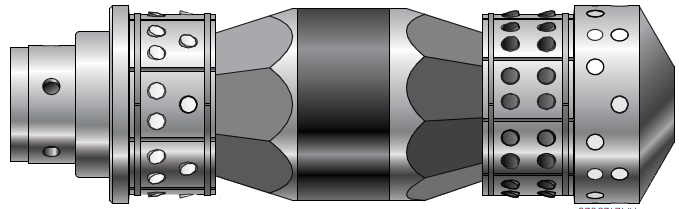

The Hydra-Jar AP double-acting hydraulic drilling jar enables jarring up or down and varying impact force to free stuck drillstring components to minimize NPT and avoid sidetracking. When run with the Accelerator AP impact tool, the Hydra-Jar AP drilling jar delivers up to 1 million lbf of impact while protecting the drillstring and surface equipment from shock.

Rugged jar design ensures consistent impact

The Hydra-Jar AP drilling jar is balanced to hydrostatic pressure through ports open to the wellbore, ensuring consistent hitting performance regardless of changes in downhole pressure or temperature. Hitting performance is further enhanced by the jars detent syste enables the jar to load and fire consistently in a broad range of downhole conditions.

The Hydra-Jar AP drilling jar has been proven in high-temperature applications worldwide as an HT technology for directional drilling and MLWD operations.

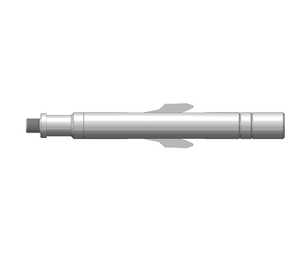

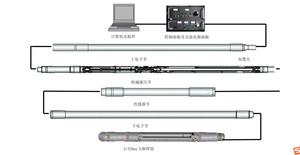

Reliable jarring in all environments with BHA compatibility

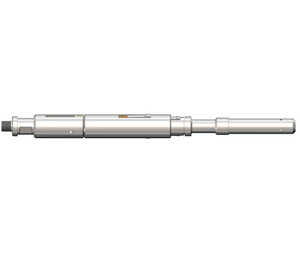

The Hydra-Jar AP drilling jar is suitable for every drilling environment on land or offshore, in vertical or deviated wells, and in ultradeep or ultrahot boreholes. Because the jar works without applied torque, directional drilling tools maintain their orientation throughout the jarring operation.

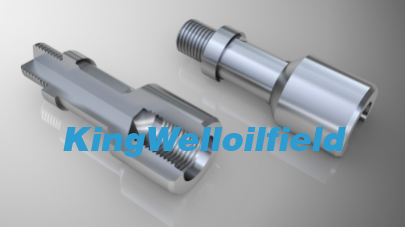

Flexible and simple jarring operation

The Hydra-Jar AP drilling jar may be run in compression or tension, enabling optimized placement in the drillstring. The jar makes up, racks, and handles like a standard-length drillpipe, reducing trip time.

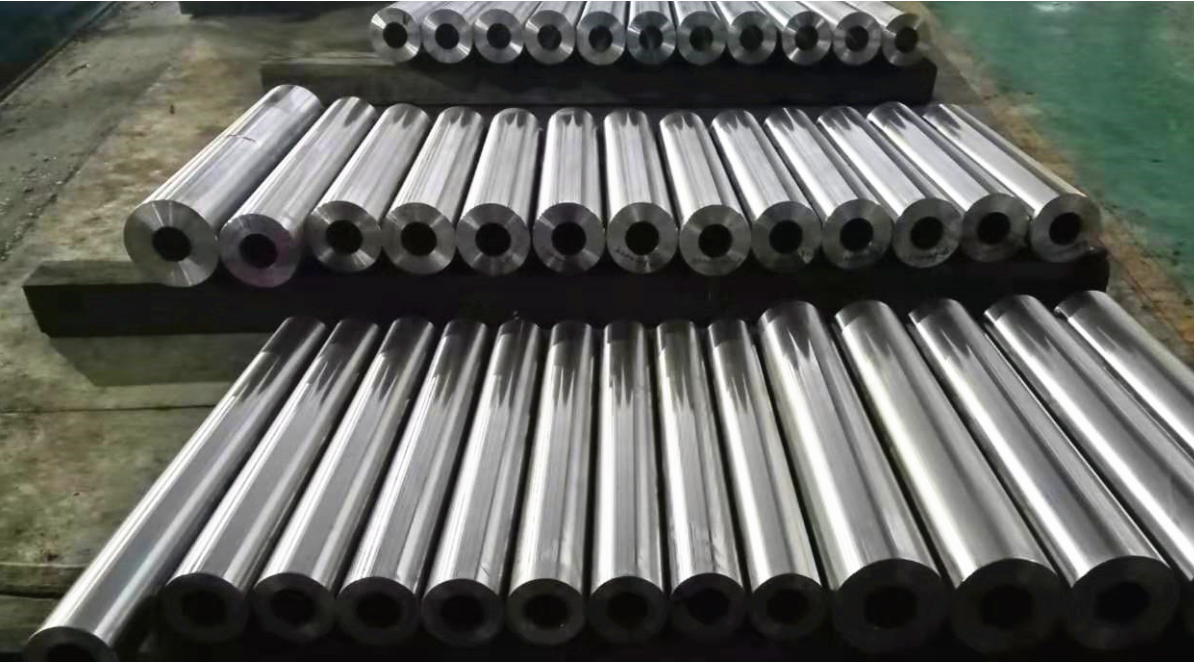

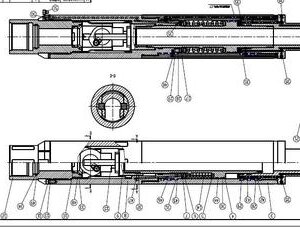

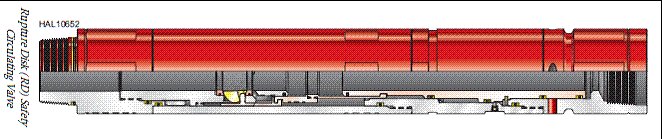

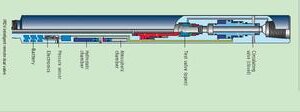

A mechanical-hydraulic double-acting drilling jar includes an inner tubular mandrel telescopingly supported inside an outer tubular housing. The mandrel and the housing each consist of a plurality of tubular segments joined together, preferably by threaded inner connections. Upper and lower pressure pistons are slidably disposed within the housing, respectively closing upper and lower substantially sealed hydraulic chambers. Longitudinal movement of the mandrel engages the collet, which in turn, translates either the upper piston or the lower piston, depending on the direction of mandrel movement. As one of the pistons is moved, fluid pressure builds in the associated hydraulic chamber, retarding further movement of the mandrel, enabling potential energy to build in the drill string. The collet is restricted from expanding until the mandrel reaches a particular point in the housing, at which time the collet expands, releasing the mandrel to rapidly collide a hammer surface thereon with an anvil surface

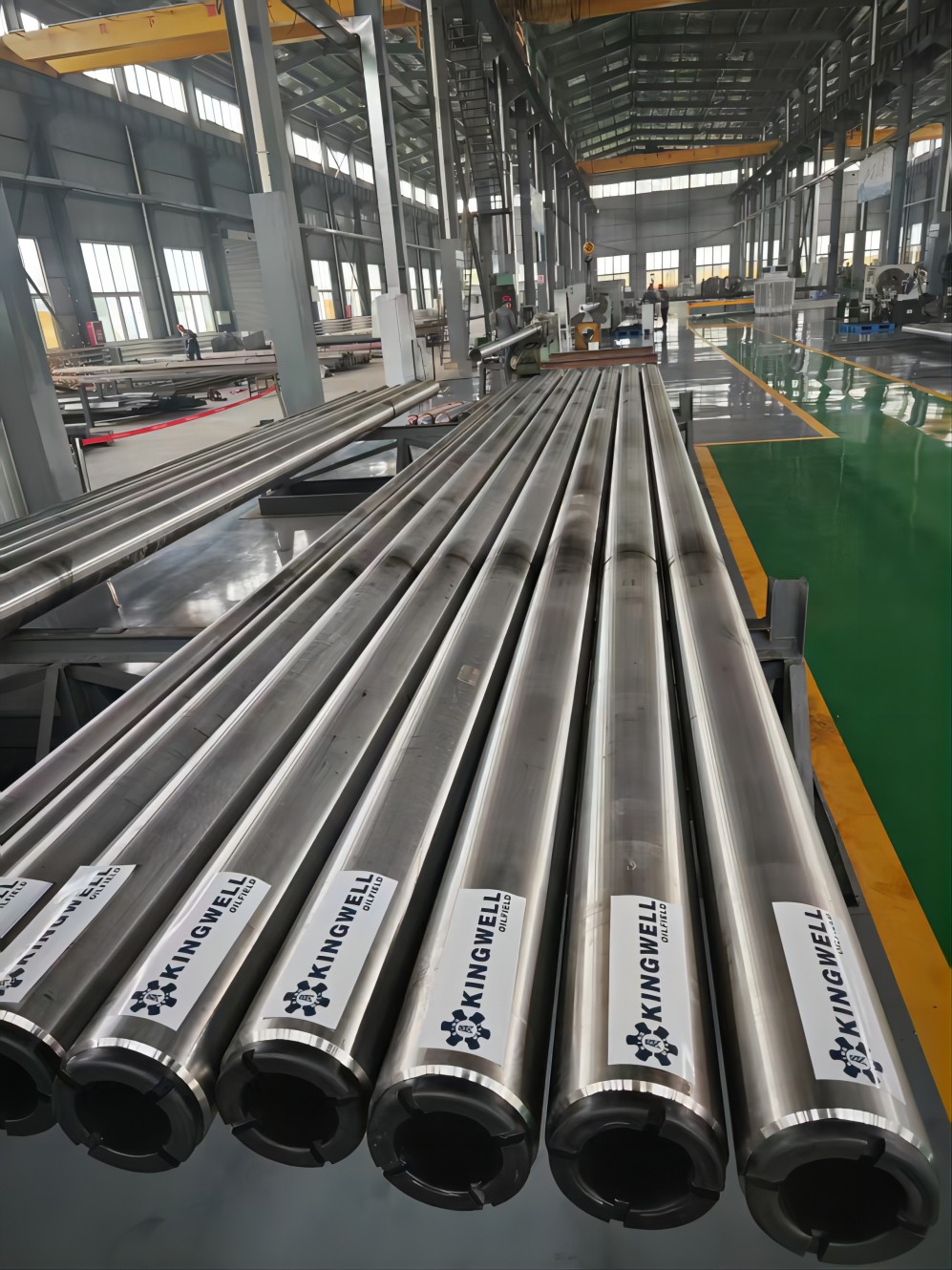

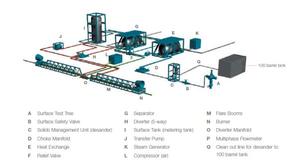

Contact your KINGWELL representative today or visit www.kingwelloilfield.com to find out how the KINGWELL helps you 。also add WhatsApp 008618729329559 or jerry@kingwelloilfield.com give u fast reply

also kingwell can degsin as Customized

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559