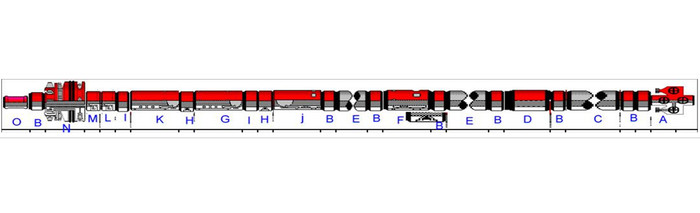

Boilers (type SZS)

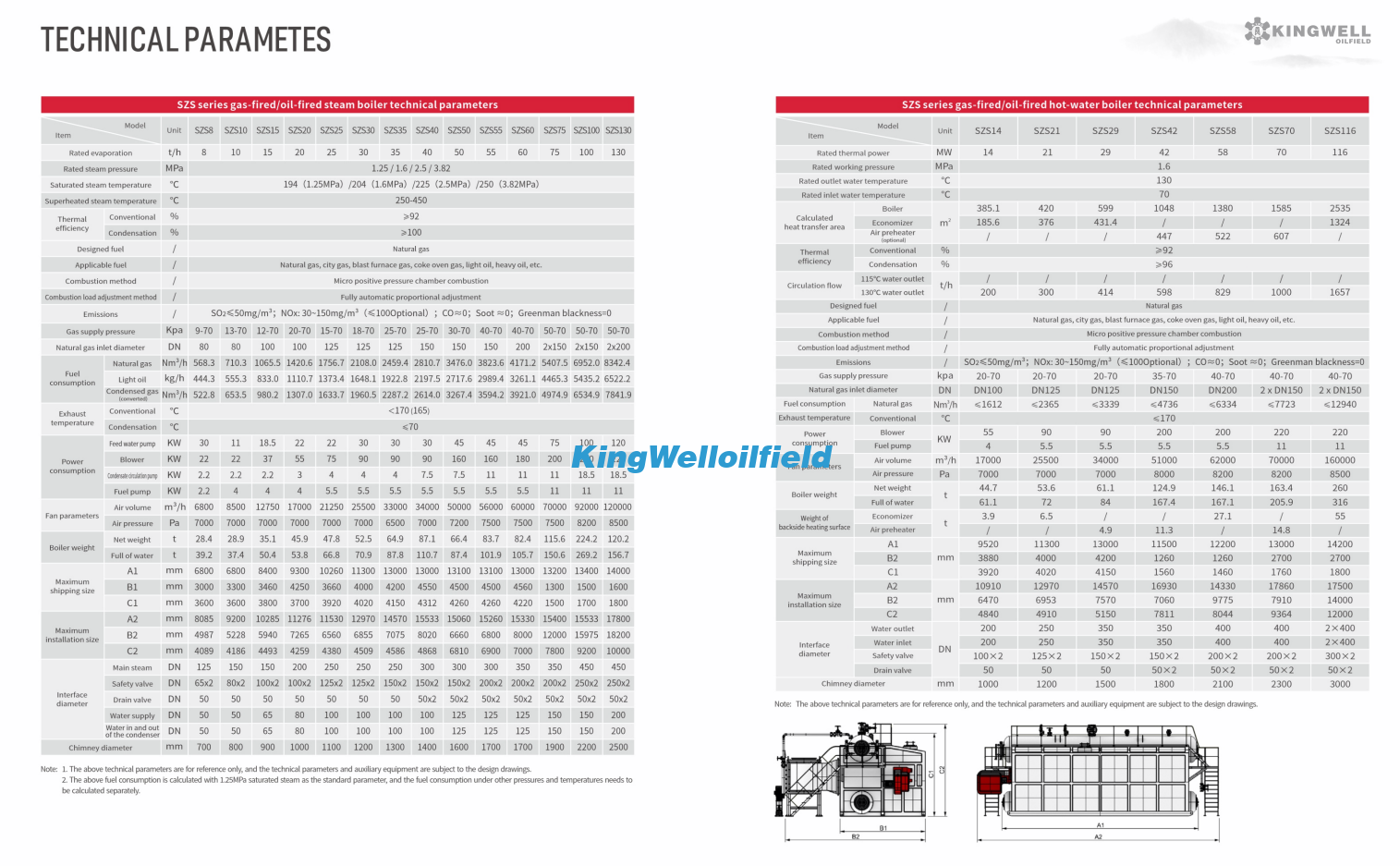

Product Parameters

Product Parameters

Types and Characteristics

Vertical Cross Tube Boiler: Compact design with 80-85% thermal efficiency, suitable for small-scale plants. Flue gas heats cross tube bundles with short water cycle paths, but evaporation capacity is limited (≤10 t/h).

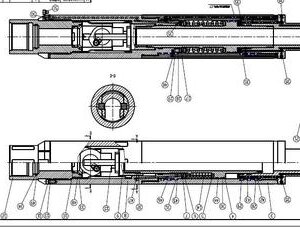

Packaged Boiler: Integrated three-pass water-fire tube hybrid structure for quick installation. High efficiency (80-85%), compatible with coal/oil/gas fuels, equipped with blowers and screw slag removers for mechanized operation.

Drum Boiler: Used in large-capacity high-parameter scenarios (e.g., power plants), achieving supercritical steam pressure (>22.1MPa) via water wall/boiling tube bundles.

Tower Boiler: Vertical flue design minimizes gas resistance, ideal for high-ash fuels (e.g., lignite), avoiding rear heat surface layout conflicts.

Materials and Corrosion Resistance

Anti-corrosion Materials: 304/316 stainless steel, Ni-based alloys (P91/T92), titanium alloys, or Ti-lined clad plates resist acidic/chloride corrosion. TA2 titanium excels in 200℃/15% Cl⁻ environments.

Anti-corrosion Techniques: Solé heavy-duty coatings (400℃ resistance, strong acid/alkali-proof), softened water treatment to remove O₂/CO₂, periodic descaling and water quality monitoring.

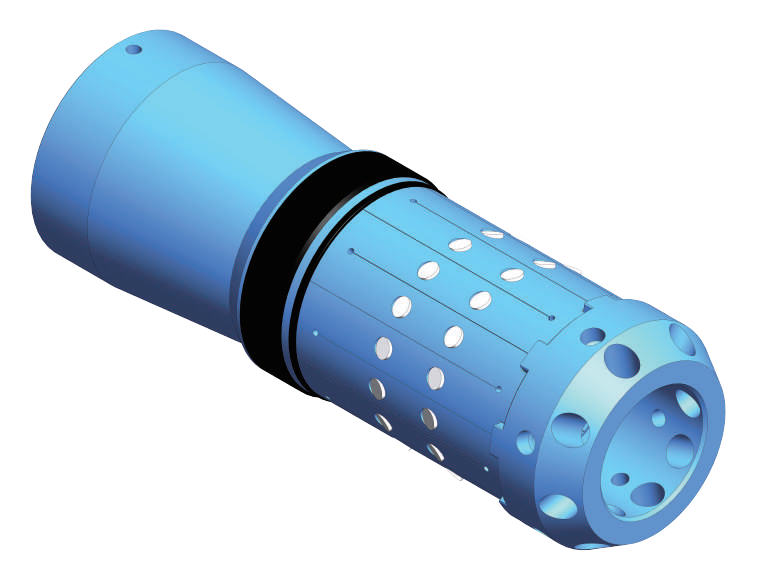

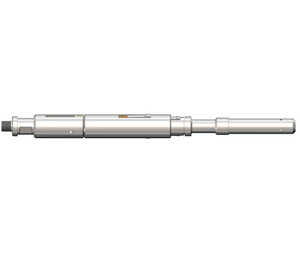

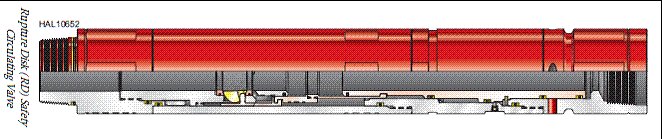

Structural Protection: Water wall tubes (φ51×3~φ63.5×3.5mm) with fins enhance heat transfer; threaded smoke tubes optimize heat exchange.

Safety Standards and Design Codes

Location & Layout: Boiler rooms must be separate from populated areas, equipped with pressure relief facilities (e.g., ≥10% glass window area). Equipment layout ensures operation/maintenance space, with overpressure interlock and low-water alarms.

Operation Management: Compliance with Steam Boiler Safety Technical Supervision Regulations, regular hydrostatic/ultrasonic testing, ensuring tensile strength ≥410MPa and hardness ≤156HB.

Eco-Efficiency: Low-NOx combustion reduces emissions; economizers recover flue gas heat; air preheaters boost combustion efficiency.

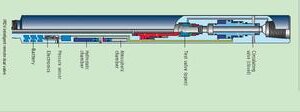

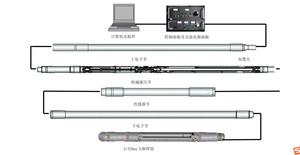

Core Components

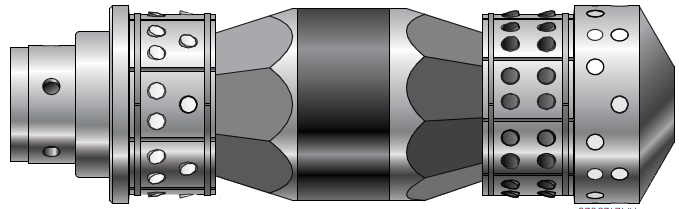

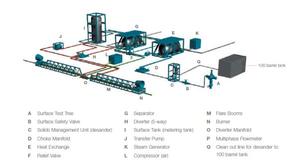

Evaporation System: Steam drum, downcomers, water walls, and headers form a natural circulation loop for water heating, vaporization, and steam superheating.

Combustion System: Furnace, burners, and ignition devices, paired with air preheaters for optimized combustion.

Rear Heat Surfaces: Superheaters, reheaters, economizers, and air preheaters in flue paths for heat recovery and steam reheating.

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559