1

1  2025-09-17

2025-09-17 Despite the best efforts, wellbore cleaning issues can still arise. The following sections will discuss common issues and provide guidance on troubleshooting and mitigation.

Identifying and Addressing Stuck Pipe Incidents

Stuck pipe incidents can occur when cuttings and debris accumulate around the drill pipe, causing it to become stuck. The following steps can be taken to identify and address stuck pipe incidents:

Monitor Drilling Parameters: Closely monitor drilling parameters such as torque, drag, and WOB to identify potential stuck pipe incidents.

Perform Cleaning Runs: Perform cleaning runs using specialized cleaning tools to remove cuttings and debris.

Adjust Drilling Fluid Properties: Adjust drilling fluid properties such as density and viscosity to improve cuttings transport and reduce the risk of stuck pipe.

Managing Drilling Fluid Losses during Cleaning Operations

Drilling fluid losses can occur during cleaning operations, particularly in wells with high permeability or fractures. The following strategies can be employed to manage drilling fluid losses:

Use Lost Circulation Materials (LCMs): LCMs can be added to the drilling fluid to help seal off lost circulation zones.

Adjust Drilling Fluid Properties: Adjusting drilling fluid properties such as density and viscosity can help reduce fluid losses.

Optimize Cleaning Tool Deployment: Optimizing cleaning tool deployment can help minimize fluid losses by reducing the amount of fluid required for cleaning.

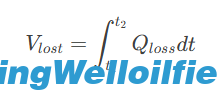

The following equation can be used to estimate the volume of fluid lost during cleaning operations:

where Vlost is the volume of fluid lost, Qloss is the fluid loss rate, and t1 and t2 are the start and end times of the cleaning operation.

Effective wellbore cleaning is crucial for ensuring the success of drilling operations. By selecting the right cleaning tools and techniques, designing optimal drilling fluids, and troubleshooting common issues, drillers can achieve efficient and effective wellbore cleaning.

Wellbore integrity hinges on effective mechanical cleanout. Debris, scale, and metallic junk obstruct tool runs and production. Vigor, a premier downhole tool manufacturer/supplier, prioritizes robust mechanical solutions. We invest heavily in developing and sourcing reliable scrapers, brushes, magnets, and bailers to physically remove obstructions from casing or open hole. Our extensive technical knowledge and supplier network ensure we deliver the precise mechanical tool for any scenario, from routine cleanouts to complex remediation. Vigor's dedication has earned global recognition for our reliable, high-performance mechanical cleanout tools. For superior downhole drilling, completion, or logging tools with a mechanical cleanout focus, contact Vigor's engineers.For more information, you can write to our mailbox kingwell@kingwelloilfield.com

![U8$}OXXZER2]{~WGELME27S U8$}OXXZER2]{~WGELME27S](https://www.kingwelloilfield.com/uploadfile/ueditor/image/202509/175809931393db30.jpg)

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559