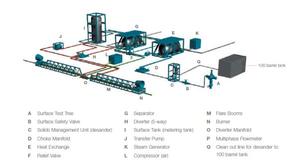

intelligent remote implementation system

Product Parameters

Product Parameters

APPLICATIONS

■ Downhole reservoir testing

■ Deviated and deepwater wells

■ HPHT and hostile wells

■ Completion operations

BENEFITS

■ Enhances safety with lower-pressure operation and no need for nitrogen in tool

■ Minimizes operating time by using automatic valve sequence commands

FEATURES

■ IRIS* intelligent remote implementation system

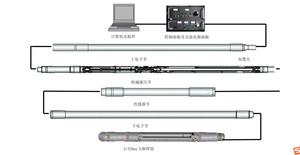

■ Downhole wireless telemetry option that allows bidirectional communication for tool command and verification

■ Reliable operation with commands unaffected by well temperature, pressure, and deviation to ensure reliable operation, even during stimulation

■ Low-pressure pulse commands or wireless commands that reduce the need to apply high casing pressure

■ Tool operations recorded in memory for postjob verification

■ Simplified hydraulic design for immunity to mud debris and well-effluent solids

■ Large-valve operating forces for tool reliability in presence of debris

■ Compatibility with all other pressure-operated tools

■ Available high-temperature version with all-ceramic multichip electronics as well as quartz-sensor pressure measurement technology

■ Mechanical override feature that provides the flexibility to reopen tester valve and continue well testing in case tester valve fails in closed position

■ Option to run two IRDV dual valves in the same string and operate both independently

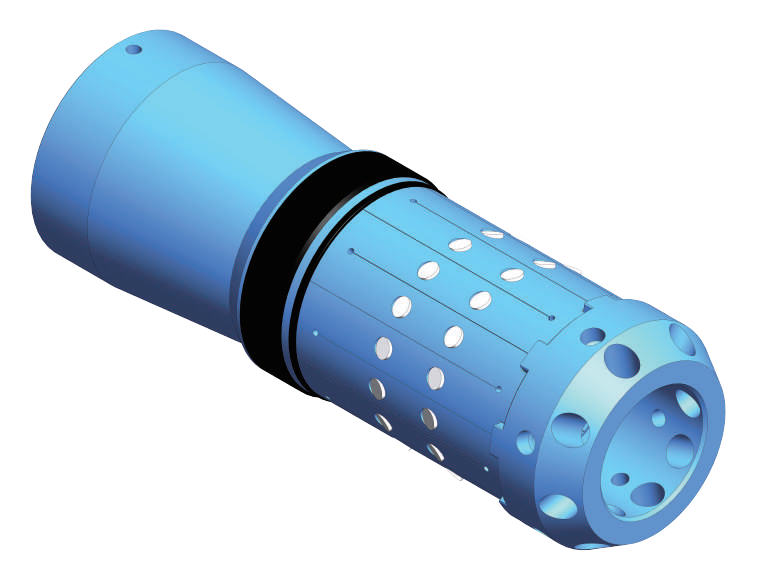

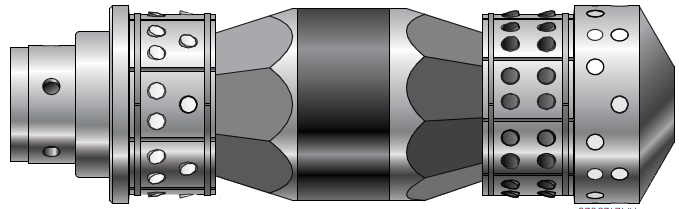

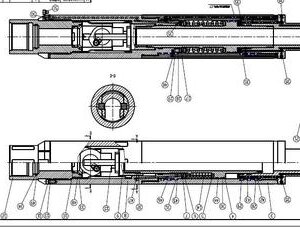

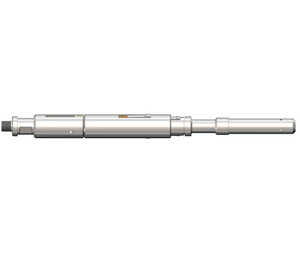

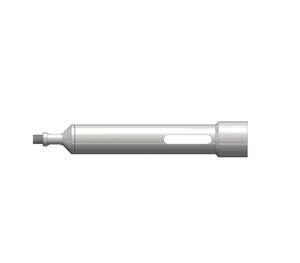

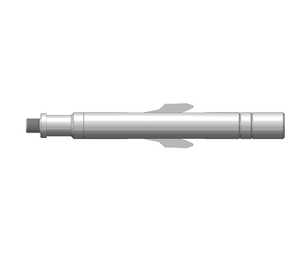

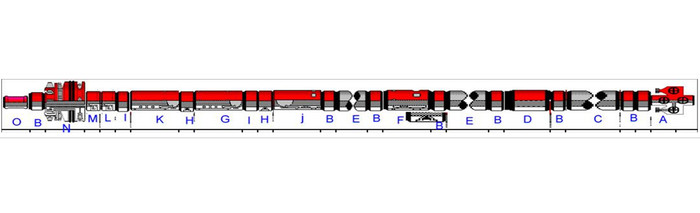

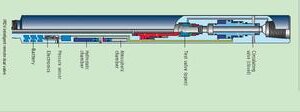

The IRDV* i combines two fullbore multicycle valves—a tester valve and a circulating valve—that can be cycled independently or sequentially for increased flexibility. The dual valve is operated by the IRIS

system, which uses low-intensity annular pressure pulses or wireless telemetry. The commands are then implemented using downhole hydrostatic pressure to operate the dual valves. Tool status is wirelessly transmitted to surface when the dual valve is deployed with optional wireless telemetry providing bidirectional communication for tool command and verification.

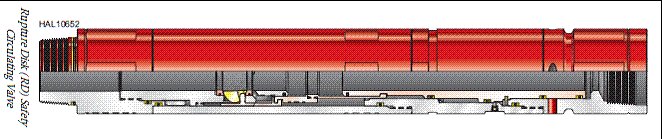

The tool’s intelligent controller provides a high level of flexibility without adding mechanical complexity. Its mechanical section is simple, with most seals and moving parts bathed in hydraulic oil at hydrostatic pressure to ensure reliable tool operation in environments with debris or heavy mud. The circulating valve has eight 1/2-in-diameter circulating ports (5/8 in for the large-bore tool), enabling higher reversing and circulating rates

to reduce rig time during operations. The IRDV dual valve has made thousands of runs in which the fluids ranged from lightweight clear brines to heavyweight mud systems.

The flexible IRIS system includes automatic valve sequences that optimize wellsite operation. The IRDV dual valve is insensitive to pressure fluctuations from the operation of other tools, common operational procedures, and hydraulic fracturing. The hydraulic system and reference

pressure for the tool are automatically referenced with the hydrostatic pressure, allowing operation going in and coming out of the well at any depth.

Enhanced with 100% ceramic multichip technology and all-quartz sensor pressure measurements,

the high-temperature version is qualified to reliably operate in reservoirs up to 410 degF [210 degC]

Specifications | |||||

Model | IRDV-BA | IRDV-CA | IRDV-KA | IRDV-KB | IRDV-HK |

Max. OD, in [mm] | 5 [127] | 5 [127] | 5.25 [133] | 5.25 [133] | 7 [178] |

Tool ID, in [mm] | 2.25 [57] | 2.25 [57] | 2.25 [57] | 2.25 [57] | 3.5 [89] |

Pressure ratings | |||||

Differential, psi [MPa] | 10,000 [69] | 15,000 [103] | 15,000 [103] | 15,000 [103] | 12,000 [83] |

Max. annular, psi [MPa] | 13,000 [90] | 21,000 [145] | 30,000 [207] | 30,000 [207] | 7,500 [52] |

Max. tubing, psi [MPa] | 15,000 [103] | 21,000 [145] | 30,000 [207] | 30,000 [207] | 20,000 [137] |

Max. opening differential, psi [MPa] | |||||

For circulating valve (if external pressure > internal pressure) | 7,500 [52] | 7,500 [52] | 7,500 [52] | 7,500 [52] | 7,500 [52] |

For tester valve (if pressure below valve > pressure above valve) | 7,500 [52] | 7,500 [52] | 7,500 [52] | 7,500 [52] | 7,500 [52] |

Min. hydrostatic required, psi [MPa] | 1,500 [10] | 3,000 [21] | 5,000 [34] | 5,000 [34] | 1,500 [10] |

Temperature rating, degF [degC] | 320 [160] | 350 [177]† | 350 [177] | 410 [210] | 350 [175] |

Length, ft [m] | 24.9 [7.6] | 27.2 [8.3] | 28.3 [8.6] | 28.3 [8.6] | 29.6 [9] |

Weight, lbm [kg] | 1,120 [508] | 1,300 [590] | 1,750 [794] | 1,750 [794] | 2,390 [1,084] |

Service (NACE MR0175/ISO 15156) | H2S, acid | H2S, acid | H2S, acid | H2S, acid | H2S, acid |

Tensile strength min. yield, lbf [kN] | 300,000 [1,334] | 300,000 [1,334] | 300,000 [1,334] | 300,000 [1,334] | 480,000 [2,135] |

Min. command pulse, psi [MPa] | 250 [1.72] | 250 [1.72] | 250 [1.72] | 250 [1.72] | 250 [1.72] |

Number of cycles‡ | 24 | 24 | 24 | 24 | 27 |

Min. battery autonomy, h | 600 | 600 | 600 | 450 | 456 |

Connection | 31/2 IF or PH-6 | 31/2 IF or PH-6 | 31/2 PH-6 | 31/2 PH-6 | Tenaris Wedge 563 |

Wireless functionality compatibility | Yes | No§ | No§ | Yes | Yes |

Global Service Hotline +86-18729329559

Global Service Hotline +86-18729329559